Calibrating your standards enables connecting them to the international system of units, while ensuring the traceability of your measurements. This approach serves to satisfy the requirements of your quality assurance protocol.

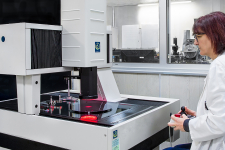

Measuring with CMMs

Thanks to our expertise in 3D metrology and the versatility of its fleet of 3D measuring machines, LNE offers the following services:

- Connecting your specific standards to the metrological chain: graduated or geometrically patterned reference gauges, templates, standard parts, etc.

- Dimensional inspection of mechanical parts: service and expertise on all types of parts: measurements by mechanical probing (measuring head, etc.) or optical non-contact measurement (laser scanner, optical sensors, etc.), GPS tolerancing, shape, orientation, position defects, etc.

Our selection of coordinate measuring machines

LNE has a fleet of three-dimensional measuring machines ranging from 1m3 to 3m3, with or without contact, point-to-point or scanning, for the inspection and calibration of your standards or industrial parts:

| Measuring capacity | Manufacturer's specifications | |

| ZEISS type ACCURA II | x 900 mm – y 1200 mm – Z 800 mm |

|

|---|---|---|

| ZEISS type UPMC 850 CARAT |

x 850mm – y 1200 mm – z 600 mm |

|

| ZEISS type CONTURA 12/24/8 | x 1200 mm – y 2400 mm – z 800 mm |

|

| MICROVU type EXCEL502UM | x 400 mm – y 500 mm – z 200 mm |

|

Connecting of CMM and machine tool standards

The connections of standards associated with CMMs and machine tools are carried out on specific test benches and under Cofrac accreditation.

Step wedge type CHECK MASTER or KOBA-step

Measuring range: 5 mm to 820 mm

- The step wedge is calibrated in a horizontal position

- • Distances are measured at the centre of the faces using an oscillating spherical touch probe with reference to a fringe-counting laser interferometer

- Optimal measurement uncertainty: U = (0.3 µm + 1.5 .10-6.L) (k=2)

Length up to 1020 mm, carry over from 820 mm (this carry over is not COFRAC accredited)

- Optimal measurement uncertainty: U =(0.5 µm + 2.5 .10-6.L) (k=2)

Accréditations

Wedges

- COFRAC accreditation calibration n°2-35 (Paris site)

Glass rulers

- COFRAC calibration accreditation n°2-1446 (Nîmes site)

List of locations and scopes available on www.cofrac.fr